Product Information

Polymers and Resin Materials

Pressure-Sensitive Adhesives

We offer pressure-sensitive adhesives for a wide range of purposes including automotive applications, electronics, architectural materials and more.

The adhesive properties can be tailored to meet customer requirements by adjusting the composition, molecular weight and functional group configuration.

In addition to solvent-borne, water-borne, and solvent-free options, we also offer a biomass grade.

For Optical Tape (High Transparency, Resistant to Moisture, Heat, and Foaming)

| Product name | Nonvolatile content (%) | Viscosity (mPa·s) | Acid value | Hydroxyl value | Toluene-free | Characteristics/notes |

|---|---|---|---|---|---|---|

| LKG-1008A | 35 | 9,000 | Yes | Yes | – | Anti-foaming properties |

| LKG-1009HS | 38 | 14,000 | No | Yes | – | Acid-free |

| LKG-1010 | 30 | 4,000 | Yes | Yes | – | Anti-foaming |

| LKG-1030 | 60 | 6,000 | No | Yes | 〇 | High solids content, acid-free |

| LKG-2110 | 100 | 5,000 | No | Yes | Solvent-free | UV syrup |

For Dicing Tape (UV-Curable Release Type)

| Product name | Nonvolatile content (%) | Viscosity (mPa·s) | Acid value | Hydroxyl value | Toluene-free | Characteristics/notes |

|---|---|---|---|---|---|---|

| LKG-1705 | 34 | 500 | No | Yes | 〇 | Grade with improved substrate adhesion |

| LKG-1715 | 34 | 350 | No | Yes | 〇 | Heat-resistant grade |

| LKG-1719 | 40 | 7,000 | Yes | Yes | 〇 | High-adhesion grade |

| LKG-1721 | 34 | 600 | No | Yes | 〇 | Standard grade |

For Masking Tape (Instant Cure, High Adhesion)

| Product name | Nonvolatile content (%) | Viscosity (mPa·s) | Acid value | Hydroxyl value | Toluene-free | Uses/characteristics |

|---|---|---|---|---|---|---|

| LKG-1426 | 55 | 6,500 | Yes | Yes | 〇 | Airtight waterproof tape / high adhesion |

| LKG-1428 | 56 | 5,500 | Yes | Yes | – | Masking tape / instant cure |

| LKG-1431 | 55 | 14,000 | Yes | Yes | 〇 |

For Industrial Tape (Heat Resistant, General Purpose, High Adhesion)

| Product name | Nonvolatile content (%) | Viscosity (mPa·s) | Acid value | Hydroxyl value | Toluene-free | Characteristics/notes |

|---|---|---|---|---|---|---|

| LKG-1201A | 32 | 2,000 | Yes | Yes | – | Heat resistant (150°C), weak adhesion |

| LKG-1206 | 40 | 1,500 | Yes | Yes | 〇 | Heat resistant (200°C), minimal adhesion |

| LKG-1410 | 51 | 14,000 | Yes | Yes | 〇 | Rebound resistant |

| LKG-1414 | 55 | 6,000 | Yes | Yes | – | High adhesion to hard-to-bond materials |

| LKG-2109 | 100 | 4,000 | Yes | Yes | Solvent-free | UV syrup |

Environmentally Friendly Products

| Product name | Nonvolatile content (%) | Viscosity (mPa·s) | Acid value | Hydroxyl value | Biomass raw materials | Characteristics/notes |

|---|---|---|---|---|---|---|

| FBM-003 | 50 | 6,000 | Yes | Yes | Yes | High biomass content, heat resistant (150°C), minimal adhesion |

| LKG-2603 | 58 | 1,000– 5,000 | Yes | Yes | No | Strong adhesion, water-borne emulsion resin |

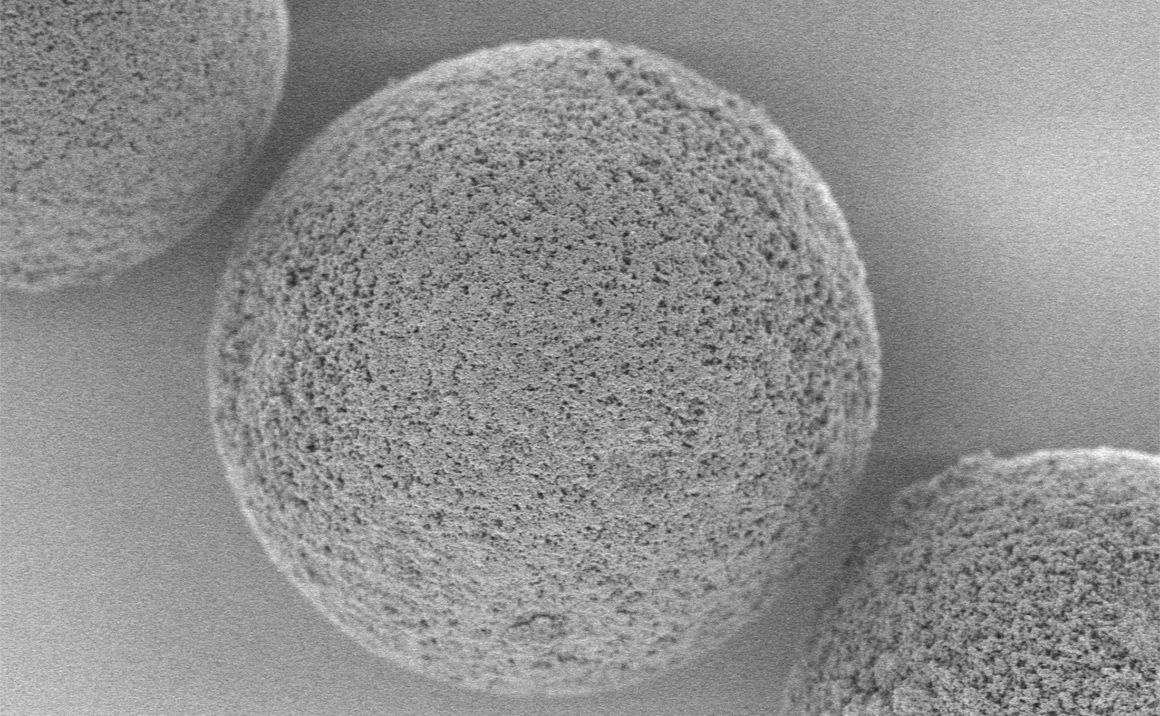

Functional Particles

Organic fine particles can be obtained by our unique polymerization technique.

We offer fine particles in various grades (acrylic, styrene, acrylic-styrene, crosslink, soft, and porous).

Adjustments of particle size (from 0.1 to hundreds of microns), degree of crosslinking (solvent resistance), polarity, refractive index, composition, and other characteristics can be made according to your requirements.

They can be used for a wide range of applications, including as matting agents, light diffusing agents, anti-blocking agents, paint additives, and more.

Anti-blocking/anti-glare

| Product name | Particle diameter (μm) | Polarity | Refractive index | Degree of crosslinking | Applications |

|---|---|---|---|---|---|

| FFP-1050 | 0.05 | Anionic | 1.54 | High | Film, toner, etc. |

| FFP-1100 | 0.1 | Anionic | 1.50 | High | Film, toner, etc. |

| FFP-8300 | 0.3 | Cationic | 1.51 | Ultra high | Film, toner, ink, etc. |

| FFP-8301 | 0.5 | Cationic | 1.54 | Ultra high | Film, toner, ink, etc. |

| FDB-001 | 1 | Anionic | 1.60 | Standard | Film, ink, coatings, etc. |

| FDB-021 | 2 | Anionic | 1.55 | Standard | Film, ink, coatings, etc. |

- Polarity, refractive index, degree of crosslinking, etc. can be adjusted according to your requirements.

Matting Agent

| Product name | Particle diameter (μm) | Polarity | Refractive index | Degree of crosslinking | Applications |

|---|---|---|---|---|---|

| FMA-430 | 5 | Anionic | 1.49 | Standard | Coatings, ink, etc. |

| FMA-520 | 20 | Anionic | 1.49 | Standard | Coatings, ink, etc. |

| FMA-581 | 80 | Anionic | 1.49 | Standard | Coatings, ink, etc. |

- Besides the above, we offer fine particle types with controlled particle morphology.

• Hollow structure: FLD series

• Porous structure: FMP series

Emulsions (Water-Borne)

| Product name | Composition | Nonvolatile content (%) | Tg (°C) | MFT (°C) | Viscosity (mPa·s) | pH | Substrates | Characteristics |

|---|---|---|---|---|---|---|---|---|

| ABH-6201 | Acrylic | 43 | -6 | 0 | 30 | 8 | PET, PVC, OPP, etc. | High transparency |

| ABH-6202 | Acrylic | 43 | 15 | 20 | 20 | 8 | PET, PVC, OPP, etc. | High transparency |

| ABH-1022 | Acrylic | 45 | -10, 70 | 5 | 80 | 8 | Sealer | High-strength core-shell |

| ABH-1023 | Acrylic/ styrene |

45 | -10, 70 | 5 | 80 | 8 | Sealer | Water-resistant core-shell |

| ABH-2012 | Acrylic | 50 | 25 | 30 | 130 | 8 | Resin for top coat | Ultra high weather resistance |

| ABH-2013 | Acrylic | 45 | 25 | 30 | 130 | 8 | Resin for top coat | Pollution resistant |

Materials for Photocopiers & Printers

We offer a lineup of toner binders and polymer charge control agents for copiers and printers.

Toner Binders

| Product name | Tg (°C) | Toluene-insoluble content (%) | Acid value (mg KOH/g) | Melt viscosity T1/2 (°C) | Mw (×1000) |

|---|---|---|---|---|---|

| FSR-051 | 63 | 25 | No | 142 | 370 |

| FSR-053 | 59 | 0 | Yes | 132 | 320 |

| FSR-055 | 54 | 32 | No | 136 | 445 |

| FSR-061 | 61 | 43 | No | 145 | 410 |

| FSR-068 | 56 | 10 | No | 130 | 290 |

| FSR-044 | 60 | 0 | No | 112 | 15 |

FCA Resin-Type Charge Control Agents for Toner

The FCA series is a series of polymer charge control agents developed by our company with our unique technology.

"Unlike conventional charge control agents, FCA series products not only exhibit charge characteristics, but also provide excellent performance in areas such as safety and transparency. They can be used effectively in electrophotographic materials such as toner, carriers, and friction charging members, as well as in electrostatic painting,

and have been widely used by many customers since their market launch in 1986.

Characteristics

| Dispersibility (compatibility) |

FCA series products combine non-polar and polar components to offer excellent dispersibility (homogeneity) and compatibility with binder resins. They can be used not only with conventional grinding methods, but also in a wide range of applications such as polymerized toners (suspension method, latex method, and dispersion polymerization method), carrier coating materials, powder painting, and more. |

|---|---|

| Transparency | FCA series products form highly transparent films in a wide mixing range (0.05–20%) with many binder resins, including styrene-acrylic, polyester, epoxy, and hybrid types. |

| Charge stability | FCA series products have stable characteristics, and the charge amount can be controlled by adjusting the quantity added. |

| Safety | FCA series products offer excellent safety as they use high molecular weight polymers and contain no heavy metals. |

| Environmental compatibility | FCA series products offer high environmental compatibility due to their insolubility in water and high molecular weight. |

| Chemical registration | Act on the Regulation of Manufacture and Evaluation of Chemical Substances, TSCA, and others |

Resin-Based External Additives

Firing Binders

We offer low-residue acrylic resin-based binders suitable for firing ceramic molding, heat-dissipating substrates, alumina, and more.

Our lineup can be customized to meet your needs, and includes powder, solvent-borne, and water-borne options.

Firing Binders

| Product name | Nonvolatile content (%) | Viscosity (mPa·s) | Tg (°C) | Molecular weight | Functional groups | Description | Solvent | Applications |

|---|---|---|---|---|---|---|---|---|

| BTF-27 | 40 | 8,000 | 53 | Medium | Acid, hydroxyl | Vehicle (solvent-borne) | Toluene/ethanol | Green sheet (high breaking strength) |

| BTF-300 | 35 | 3,500 | 8 | High | Acid, hydroxyl | Vehicle (solvent-borne) | Toluene/ethyl acetate/ethanol | Green sheet (plasticizer-free) |

| EMK-02 | 50 | 150 | 30 | High | Acid | Vehicle (water-borne) | Water | Green sheet (water-borne type) |

| MSP-11 | 30 | 19,000 | 23 | Medium | – | Vehicle (solvent-borne) | Dihydroterpineol | Paste (flexible) |

| MM-2002-1 | 100 | – | 51 | Medium | – | Solid resin | Solvent-free | Paste (good thermal decomposition characteristics) |

Urethane Resins

Our urethane resin product lineup primarily consists of non-yellowing water-borne dispersions, which are used as binders for inkjet inks, binders for coatings and inks, and more.

Efforts are also progressing on addressing environmental concerns; we now offer NMP-free and tin catalyst-free options.

Urethane Dispersions (Water-Borne)

| Product name | Nonvolatile content (%) | 100% Mod. (N/mm2) | Max. Mod. (N/mm2) | Elongation at break (%) | Compatible materials | Applications | Characteristics |

|---|---|---|---|---|---|---|---|

| UST-1401 | 35 | 3 | 20 | 600 | PET, PVC, PE, etc. | Binders for inkjet inks, etc. | Non-yellowing |

| USC-2101 | 35 | 2 | 10 | 800 | Cotton, polyester, silk, etc. | Binders for inkjet inks, etc. | High moisture and abrasion resistance |

| USC-4315 | 33 | *1 | *1 | *1 | Wood, films | Coatings, inks | Toughness |

| UST-2240 | 32 | 15 | 26 | 400 | Wood, films | Coatings, inks (primer) | Conformability |

*1 Measurement not possible due to high hardness.

Block Polymers

We have developed a range of block polymer products with our unique technologies.

By incorporating both hard and soft resin segments into a single polymer, we are able to separate their functions, enhancing the properties of the resulting polymer to levels previously unattainable with random polymerization. Block polymers can be considered for a wide variety of applications, including pressure-sensitive adhesives, substrates, and dispersants.

For Pressure-Sensitive Adhesives

| Product name | Nonvolatile content (%) | Hard segment (%) | Tg (°C) | Acid value | Adhesive strength (to stainless steel) | Applications | Solvent | Characteristics |

|---|---|---|---|---|---|---|---|---|

| FBP-003 | 40 | 17 | -55 | Yes | 22 N | Structural tape | Ethyl acetate | High adhesive strength, high shear strength |

| FBP-004 | 40 | 15 | -55 | Yes | 28 N | Double-sided tape | Ethyl acetate | Strong adhesion |

| FBP-006 | 28 | 10 | -60 | Yes | 16 N | Double-sided tape | Ethyl acetate | Strong adhesion, low rise in adhesive force |

For Substrates

| Product name | Nonvolatile content (%) | Hard segment (%) | Acid value | Tensile strength (MPa) | Elongation (%) | SAFT (°C) | Solvent | Characteristics |

|---|---|---|---|---|---|---|---|---|

| FBP-007 | 23 | 33 | Yes | 4.5 | 600 | 125 | Ethyl acetate | High temperature resistance, high stress |

| FBP-010 | 30 | 15 | Yes | 5.2 | 1,050 | 101 | Ethyl acetate | High stress, high elongation |

| FBP-020 | 23 | 19 | No | 35 | 250 | 118 | Ethyl acetate | Base material for decorative film, acid-free |

Dispersants

About the Division

For an introduction to the business division, its strategies, and where its products are used, please refer to the business overview page.