R&D

At Fujikura Kasei, the engineering departments of each business are centralized at a single location.

This facilitates the sharing of technical information and promotes cross-disciplinary interaction, leading to the creation of innovative technologies.

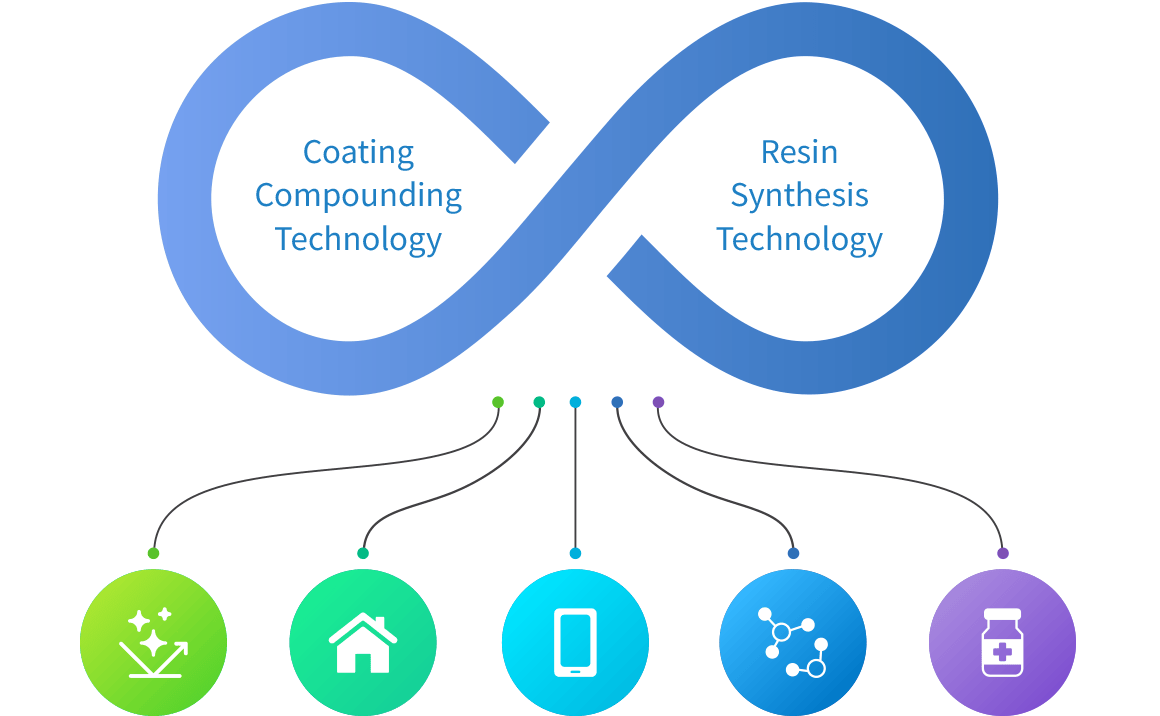

Core Technologies

Fujikura Kasei’s business is supported by two core technologies: coating formulation technology and resin synthesis technology. These are used to create a variety of products.

Our coating formulation technology derives optimal solutions by combining a wide variety of raw materials, enabling the development of coatings that offer workability, functionality, and design characteristics tailored to specific applications.

Our resin synthesis technology is not only used to impart functionality through the control of molecular weight, composition, and structure, but also to produce a variety of product forms such as solutions, aqueous solutions, and powders.

R&D Efforts & Policies

Management and Talent Strategies Focused on Research and Development

To offer development tailored to customers’ needs and create innovative technologies, we have actively invested in research and development on an ongoing basis.

Going forward, we will strive to enhancing our technological ability from a variety of aspects including people, facilities, and systems, under the vision of “Fujikura Kasei = Technology.”

Ratio of R&D Expenses to Sales

5.2% (consolidated)

8.4% (non-consolidated)

(as of March 2025)

Ratio of Employees Employed at R&D Center

30.9%

(non-consolidated)

(as of March 2025)

Ratio of Tangible Fixed Assets Belonging to R&D Center

22.3%

(non-consolidated)

(as of March 2025)

Sharing Technology Across Divisions

At our R&D Center, where researchers of different disciplines are gathered together at a single location, daily interactions frequently transcend the boundaries of researchers’ respective divisions. Moreover, regular technical exchange meetings are held to provide a platform for sharing information throughout the facility.

R&D Process

Below is an overview of the general development process. We can flexibly adapt to specific situations, so please feel free to contact us first.

-

Contact

Please contact us via the contact form or by phone, etc.

-

Confirmation of Required Performance

Please share details about the desired product specifications, deadline, and cost, etc.

We can assist you face to face, online, or over the phone.

Feel free to ask for samples of products we sell. -

Development, In-house Evaluation of Sample Products

We conduct in-house screening on samples to provide.

-

Sample Submission

We submit laboratory-scale samples to the customer.

-

Customer Evaluation and Feedback

We compare the feedback with the in-house evaluation results.

A meeting is held to prepare for submission of the next set of samples. -

Scale-Up Evaluation

We scale up from laboratory products to pilot products, and then to mass produced-products.

-

Mass Production

The customer performs a final validation of the performance of the mass-produced products.

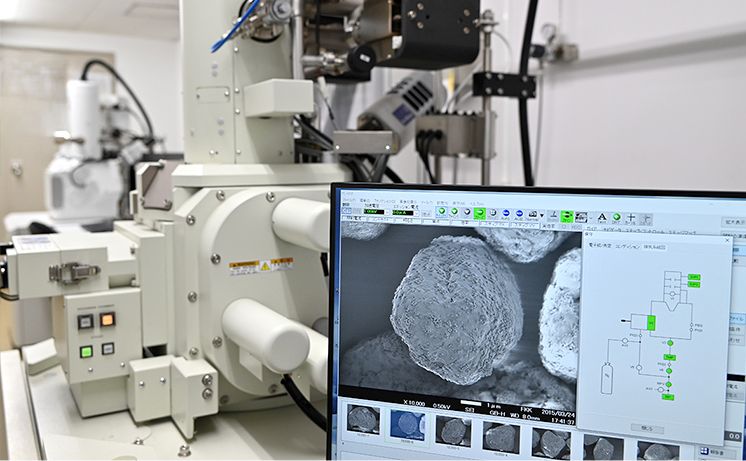

Evaluation & Analysis Equipment

In order to improve the correlation between the results of in-house evaluations and customers’ own sample evaluations, and to increase the speed of development, we have introduced a variety of evaluation and analysis devices.

We are committed to development that focuses not only on coating performance but also on workability.

Washinomiya R&D Center

At the R&D Center, our technical development hub, we handle a wide range of products with different characteristics. Therefore, to ensure efficient development, the testing area is divided into sections by product group.

Meanwhile, the office area has been made into a common space to facilitate the exchange of a wide range of information.

For inquiries about product development, please contact us via the form below.