Product Information

DOTITE® Conductive Resin Material

Characteristics of DOTITE®

DOTITE® is the brand name and general term for Fujikura Kasei’s electronics materials centered on conductive resin materials.

For detailed characteristics and information on choosing a product, please refer to the page linked below.

Electrically Conductive Adhesives

Our adhesives are widely applicable for addressing challenges in soldering and welding, and we offer a diverse range of product lines to accommodate various application methods and materials.

Products for Electronic Components

The product lines below are high-performance electrically conductive adhesives developed for the microelectronics field.

They can be used to solve a wide range of challenges in soldering and welding, such as to provide conductive bonding as a solder replacement where heat-sensitive are present in electronic components, or for mounting electronic components on printed boards (PCB/PWB).

Our lineup includes products with characteristics such as electrical conductivity, adhesive strength, heat resistance, and workability, and we offer a wide range of variations, including solvent-borne and solvent-free types, different curing conditions, viscosities, and more, tailored to specific applications and methods.

| Product name (code) | Volume resistivity (Ω·cm) |

Adhesive strength | Pyrolysis temp. (°C) |

Young’s modulus | Curing conditions | Storage conditions | Thinner | Characteristics |

|---|---|---|---|---|---|---|---|---|

| FA-705BN | 2×10-3 | 9 kgf (lead wire) |

250*1 | 5GPa*3 | 150℃ 30min | Refrigerated | Solvent-free | Compatible with a wide range of applications, good contact resistance |

| XA-874 | 8×10-5 | 20N/mm2 | 350*1 | 4GPa*3 | 150℃ 30min | Frozen | Solvent-free | High heat resistance, high strength, extensively used in automotive applications |

| XA-910 | 4×10-4 | 20N/mm2 | 350*1 | 7GPa*3 | 100℃ 60min 150℃ 30min 180℃ 7min |

Frozen | Solvent-free | Curable at low temperatures, high heat resistance |

| AA07 | 2×10-4 | 12N/mm2 | 300*1 | 3GPa*3 | 150℃ 60min | Frozen | Solvent-free | Excellent flexibility |

| AA2121-AN6 | 5×10-4 | 12N/mm2 | 335*1 | 6GPa*3 | 80℃ 60min | Frozen | Solvent-free | Curable at low temperatures, good storage stability |

| AA2119-G4 | 5×10-4 | 20N/mm2 | – | – | 80℃ 30min/70℃ 60min/60℃ 90min | Frozen | Solvent-free | Curable below 80℃ |

| AA2201-A | 6×10-4 | 5N/mm2 | – | 6GPa*3 | Hot plate 210℃ 1min (Oven 150℃ 30min also possible) |

Frozen/refrigerated | Solvent-free | Capable of rapid curing, good storage stability |

| A-3N/C-3 | 2×10+1 | 9kgf (lead wire) |

245*1 | 1GPa*3 | 150℃ 30min | Room temperature | Solvent-free | Dual-component, carbon conductive particles |

| XA-5651A | 2×10-4 | 16N/mm2 | 345*1 | 3GPa*3 | 180°C, 60 min or reflow oven 200°C, 10 min | Frozen | – | Excellent reliability when used on tin electrodes |

| AA1221-G2-1 | 8×10-5 | 35N/mm2 | 360*1 | 6GPa | 150℃ 30min | Frozen | Solvent-free | Can be used on tin electrodes |

| AA55 | 0.8×10-4 | 6N/mm2 | 260*1 | 6GPa*3 | 100℃ 30min | Liquid A: refrigerated Liquid B: refrigerated |

SH Thinner | Dual-component, curable at low temperatures |

| FA-750 | 4×10-4 | 3N/mm2 | 345*2 | 500MPa*3 | 150℃ 30min | Refrigerated | – | High reliability, high flexibility Workability adjustable with dilution |

- Temperature at which 1% weight loss occurs in air, determined with thermogravimetric analysis.

- Temperature at which 1% weight loss occurs in nitrogen, determined with thermogravimetric analysis.

- Determined with dynamic mechanical spectroscopy.

All of the above product lines comply with the European RoHS Directive.

The above values are all representative values, and do not represent full product specifications.

Conductive Adhesives for Crystal Devices

Our widely used product lines dominate such a large share of the crystal device market that companies tell us, “We couldn’t have commercialized our products without DOTITE®.”

Combining conflicting qualities such as flexibility, conductivity, adhesive strength, and heat resistance, our products continue to meet our customers’ requirements.

Moreover, we offer a range of product lines tailored market trends such as advancements in component miniaturization and reliability.

| Product name (code) | Resin | Volume resistivity (Ω·cm) |

Adhesive strength | Pyrolysis temp. (°C) |

Young’s modulus | Curing conditions | Storage conditions | Characteristics |

|---|---|---|---|---|---|---|---|---|

| XA-5243 | Silicone | 1.5×10-4 | 1.2*2 | 500*1 | 200MPa | 200℃ 60min | Frozen | Extensive use in tuning fork crystal oscillators |

| AA1101-S | Silicone | 1.5×10-4 | 1.0*2 | 500*1 | 130MPa | 180℃ 60min | Frozen | Standard product |

- Temperature at which 1% weight loss occurs in nitrogen, determined with thermogravimetric analysis.

- DSTM-510, unit: kgf

All of the above product lines comply with the European RoHS Directive.

The above values are all representative values, and do not represent full product specifications.

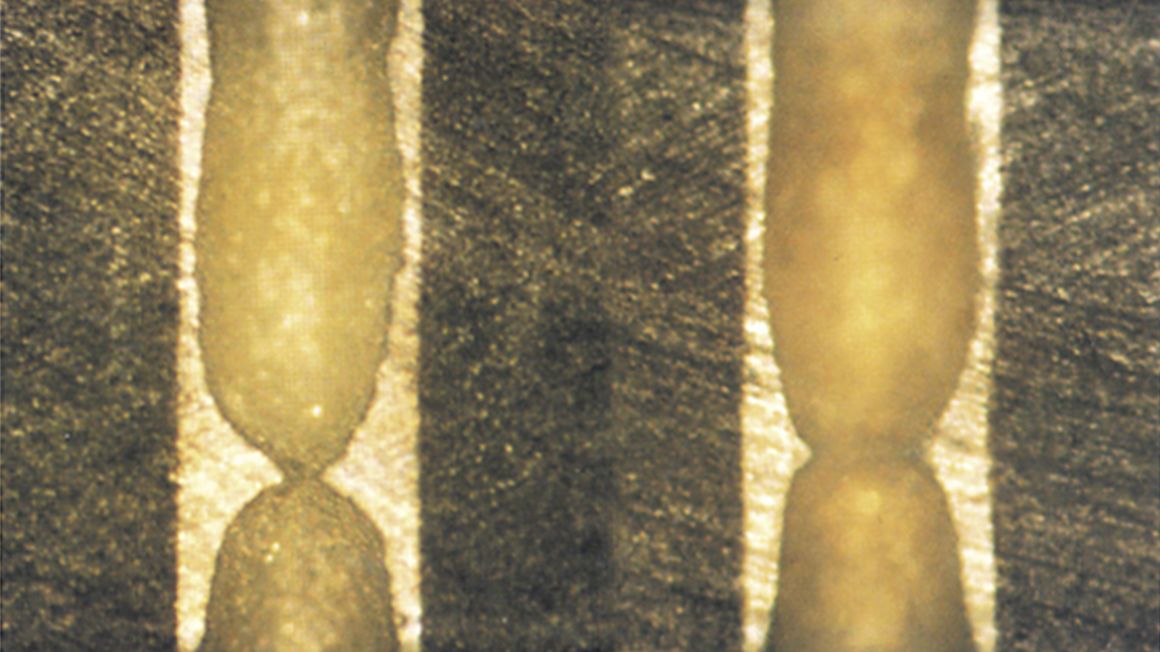

Circuitry, Electrode, and Connector Materials for PCBs

Applications

We offer a lineup of conductive and contact materials, as well as materials for sliding electrodes, that can be used in rigid printed boards (PWBs and PCBs). These include materials for inexpensive double-sided “silver through-hole boards,” as well as “silver jumper boards,” which provide a simple and inexpensive way to create two-layer boards.

These materials combine reliability and printability in a well-balanced manner, and boast a high market share with a long history of adoption.

| Product name (code) | Applications | Filler | Volume resistivity (Ω·cm) | Curing conditions | Storage conditions | Thinner | Features |

|---|---|---|---|---|---|---|---|

| XA-1079TF | For through holes | Ag | 2×10-4 | 150℃ 30min. | Refrigerated | A Thinner | Cost-effective standard product |

| XC-223 | For contacts/jumpers | C | 3×10-2 | 150℃ 30min. | Refrigerated | P Thinner | Good durability |

All of the above product lines comply with the European RoHS Directive.

The above values are all representative values, and do not represent full product specifications.

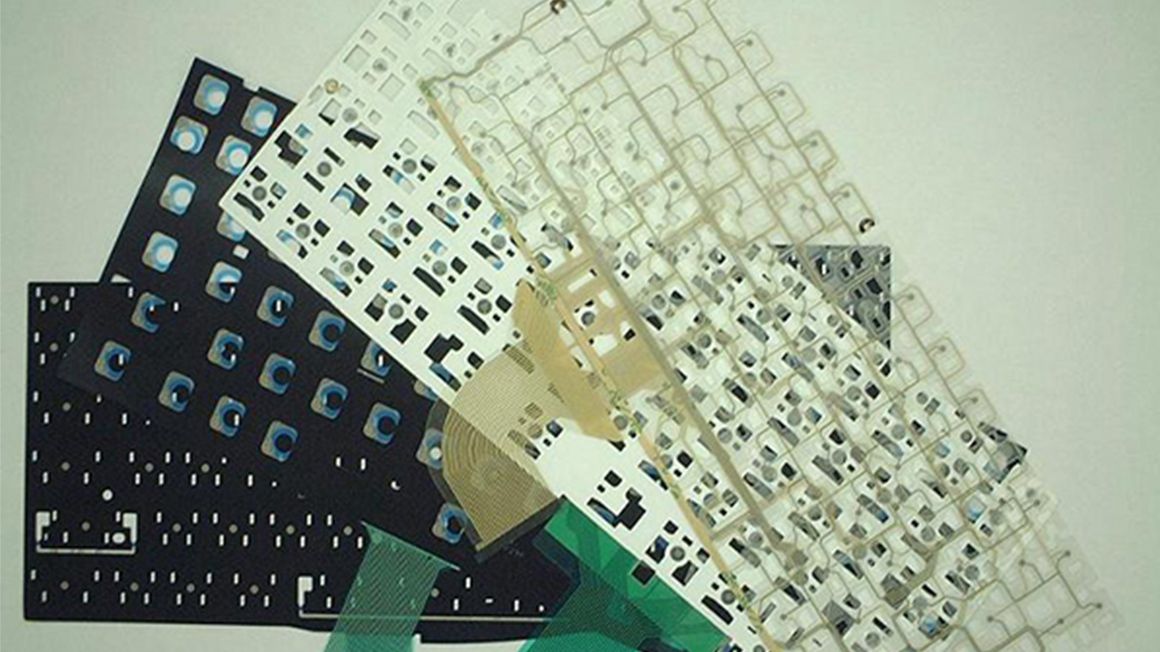

Materials for Printed Electronics (PE)

Characteristics

These products offer a diverse range of functional qualities, including adhesion to various plastic materials such as PET films, polyimide (PI) films, and polycarbonate (PC), as well as flexural resilience and conformability to flexible materials. In addition, they can offer low resistance values, high-precision printability, and compatibility with a wide range of printing methods.

Besides conductive materials, we also offer protective insulating materials, pressure-sensitive adhesives for film lamination, and adhesives for mounting components.

Applications

Screen Printing

| Product name (code) | Applications | Filler | Volume resistivity | Curing conditions | Storage conditions | Compatible substrates |

Features |

|---|---|---|---|---|---|---|---|

| FA-323 | Automotive sensors FPC jumpers |

Ag | ≤4.0×10-5 Ω·cm | 150℃10min | Room temperature | PET, PI, glass | Excellent reliability |

| XA-3992 | FPC replacement | Ag | 4.5×10-5 Ω·cm | 150℃30min | Refrigerated | PET, PI, glass | Polyimide (PI) film Good adhesion |

| FA-333 | Membrane switches |

Ag | ≤4.0×10-5 Ω·cm | 120℃ 10min. | Room temperature | PET, glass | Curable at low temperatures, good conductivity |

| FA-345 | Membrane switches |

Ag | ≤6.0×10-5 Ω·cm | 150℃30min | Refrigerated | PET, glass | Suitable for high-resolution printing, excellent flexural resilience |

| FA-353N | Membrane switches |

Ag | ≤5.0×10-5 Ω·cm | 150℃30min | Refrigerated | PET, glass | Good printability, excellent flexural resilience |

| XA-3927 | Membrane switches |

Ag | 4.2×10-5 Ω·cm | 150℃30min | Refrigerated | PET, glass | Low resistivity, excellent flexural resilience |

| FA-451A | Antenna formation | Ag | ≤3.0×10-5 Ω·cm | 150℃30min | Room temperature | PET, glass | Low resistivity, used in automotive applications |

| XA-3513 | Biomedical sensors | Ag/AgCl | ≤5.0×10-4 Ω·cm | 150℃30min | Refrigerated | PET | Ag: AgCl ratio adjustment available |

| XA-3737 | Capacitive touch switches |

Ag | 1.0×10^−4 Ω·cm | 125℃30min | Refrigerated | PC | Can be molded after printing and curing, ideal for in-mold electronics circuitry, good stretchability |

| XA-3993 | Plating substrate | Ag | 4.0×10-5 Ω·cm | 120℃30min | Room temperature | PET | Permits formation of plated electrodes with electroless plating, enabling components to be mounted with solder |

| XC-3236 | Circuit protection, connector electrodes | C | 1 kΩ/□ (sheet resistance) | 150℃30min | Refrigerated | PET, glass | C paste for resistor formation, retains resistance to sliding wear |

| XC-3237 | Circuit protection, connector electrodes | C | 20 kΩ/□ (sheet resistance) | 150℃30min | Refrigerated | PET, glass | C paste for resistor formation, retains resistance to sliding wear |

| XC-3050 | Circuit protection | C | ≤1.0×10-1 Ω·cm | 80℃30min | Refrigerated | PET | Curable at low temperatures, good conductivity |

| FC-415 | Circuit protection | C | ≤2.0×10-1 Ω·cm | 150℃20min | Refrigerated | PET, PI | Good anti-blocking performance |

| FC-435 | Circuit protection, connector electrodes | C | ≤1.0×10-1 Ω·cm | 150℃30min | Refrigerated | PET | Suitable for fine line printing, excellent abrasion resistance |

- When used on some varieties of polycarbonate (PC) material, the solvents contained in DOTITE® may cause discoloration or other defects. Confirming compatibility before use is recommended;

materials designed for PC are also available.

All of the above product lines comply with the European RoHS Directive.

The above values are all representative values, and do not represent full product specifications.

Unless otherwise specified, the above products are designed to be suitable for screen printing.

Diverse Printing Technologies

| Product name (code) | Applications | Filler | Volume resistivity (Ω·cm) |

Curing conditions | Storage conditions | Compatible substrates |

Features |

|---|---|---|---|---|---|---|---|

| XA-3851 | Antenna formation | Ag | 2×10-5 | 80℃ 30min. | Room temperature | PET, PC* | Can be used for pad printing after dilution with special thinners |

| XA-4004 | Antenna formation | Ag | 1.8×10-5 | 120℃10min | Refrigerated | PET | Standard product for gravure printing Can also dry at room temperature |

| XA-3609 | Printed circuits | Ag | 3×10-5 | 130℃ 30min. | Frozen | PET, ITO glass | Standard product for gravure offset/ flexography printing |

- When used on some varieties of polycarbonate (PC) material, the solvents contained in DOTITE® may cause discoloration or other defects. Confirming compatibility before use is recommended; materials designed for PC are also available.

All of the above product lines comply with the European RoHS Directive.

The above values are all representative values, and do not represent full product specifications.

Unless otherwise specified, the above products are designed to be suitable for screen printing.

Auxiliary Materials

| Product name (code) | Applications | Filler | Volume resistivity (Ω·cm) |

Curing conditions | Storage conditions | Compatible substrates |

Features |

|---|---|---|---|---|---|---|---|

| XA-472 | SMD mounting | Ag | 3×10-4 | 150℃ 30min. | Refrigerated | PET | Good conductivity |

| XB-3136 | Insulation, circuit protection | – | – | 150℃ 30min. | Room temperature | PET, PI | Good insulation properties and flexural resilience |

| XB-114 | Membrane switches |

– | – | 140℃ 10min. | Room temperature | PET | Good printability, good holding power between PET layers |

| XB-110 | Potting | – | – | 80℃ 60min. | Room temperature | PET | SMD reinforcement |

- When used on some varieties of polycarbonate (PC) material, the solvents contained in DOTITE® may cause discoloration or other defects. Confirming compatibility before use is recommended;

materials designed for PC are also available.

All of the above product lines comply with the European RoHS Directive.

The above values are all representative values, and do not represent full product specifications.

Unless otherwise specified, the above products are designed to be suitable for screen printing.

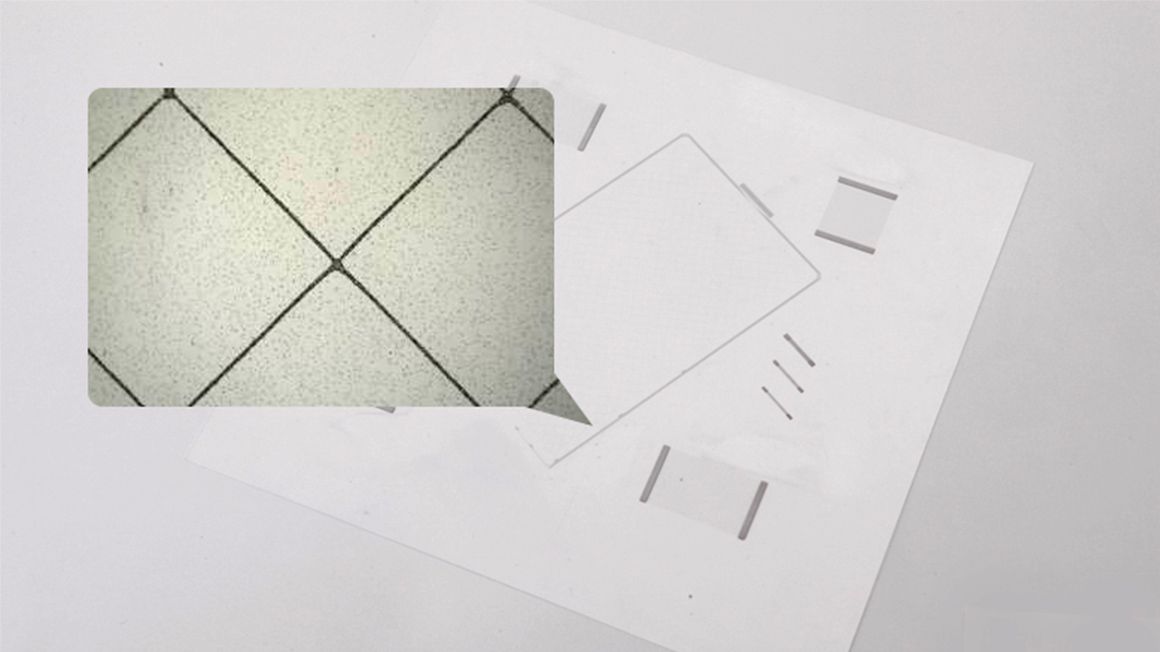

Circuitry and Insulating Paste Materials for Touch Panels

Electrically conductive pastes suitable for fine line printing as an ITO film replacement or for narrow bezel applications.

We offer insulating pastes for a diverse range of uses.

Paste Materials for Touch Panel Circuitry

We provide circuitry and insulating paste materials for resistive touch panels, a widely used and proven technology. We also offer ITO replacements for capacitive touch panels such as those commonly found in smart phones and other mobile devices, as well as electrically conductive paste materials suitable for use in fine-line circuit printing techniques for narrow-bezel purposes.

| Product name (code) | Volume resistivity (Ω·cm) |

Curing conditions | Storage conditions | Thinner | Applicable methods | Features |

|---|---|---|---|---|---|---|

| FA-410 | 10×10-5 | 140℃ 20min* 80℃ 30min |

Refrigerated | SC-0030 Thinner | Screen printing | For use on ITO films. Suitable for low-temperature drying. Used in resistive touch screens. |

| XA-436 | 7×10-5 | 150℃ 30min | Refrigerated | P Thinner | Screen printing | For ITO glass substrates. Extensively used in applications where high reliability is essential. |

| XA-3972 | 10.0×10-5 or less | 140℃ 20min | Refrigerated | SC-0030 Thinner | Screen printing | Good adhesion on ITO glass and ITO films |

| XA-3609 | 3×10-5 | 130℃ 30min | Frozen | SC-0024 Thinner | Gravure offset printing |

For high-resolution printing as an ITO replacement |

| XA-3512 | 5×10-5 | 140℃ 20min* 130℃ 10min |

Refrigerated | SC-0030 Thinner | Screen printing | Good printability |

- We recommend these for applications where coating durability, including resistance to salt spray, abrasion, etc., is particularly required.

All of the above product lines comply with the European RoHS Directive.

The above values are all representative values, and do not represent full product specifications.

Insulating Materials for Touch Panel

Starting with DOTITE® SN-8400C, which has an outstanding track record as an insulating material for touch panels, we offer a range of products with various functionalities, including high-transparency resist insulation and protective material.

| Product name (code) | Appearance | Curing conditions | Insulation resistance | Storage conditions | Features |

|---|---|---|---|---|---|

| XB-3253 | Transparent | 150℃ 30min | ≥1012 Ω | Cool, dark place at room temperature | Excellent transparency |

| SN-8400C | White | ≥800 mj/cm2 (cumulative) | ≥1012 Ω | Room temperature (30°C or below) | Extensively used |

All of the above product lines comply with the European RoHS Directive.

The above values are all representative values, and do not represent full product specifications.

Room Temperature Drying Type

Doesn’t the name “DOTITE®” bring this type to mind? That’s how widely this series is used.

Applications

This type dries at room temperature, and is particularly effective for materials like plastics that cannot be heated after application.

These are widely used for applications such as enhancing the conductivity of screws and rivets, providing simple conductive adhesion for fixing SEM samples, repairing circuits, and providing a substrate for electroplating.

| Product name (code) | Volume resistivity (Ω·cm) |

Drying conditions | Storage conditions | Thinner | Applicable methods | Features |

|---|---|---|---|---|---|---|

| D-362 | 7×10-4 | 25℃ 3H. 100℃ 30min. |

Room temperature | S Thinner, SP-2 Thinner, toluene | Paintbrush, spatula, spraying, dispensing* | Quick drying, good adhesive properties, enhances screws and rivets |

| D-500 | 8×10-5 | 25℃ 3H. 100℃ 30min. |

Room temperature | S Thinner, SP-2 Thinner, toluene | Paintbrush, spatula, spraying* | Good conductivity |

| D-550 | 1×10-4 | 25℃ 1H. 100℃ 5min. |

Room temperature | S Thinner, SP-2 Thinner, toluene | Paintbrush, spatula, spraying* | Extensively used for fixing SEM samples |

- For spraying, we recommend diluting with thinner before use.

All of the above product lines comply with the European RoHS Directive.

The above values are all representative values, and do not represent full product specifications.

EMI Shield Type

These can be applied using paint brushes or spray guns, or with screen printing (including vacuum printing), and can shield against interference ranging from the kHz to the GHz bands.

EMI Shielding

Characteristics

As we enter an era of full-blown EMI/EMC, the merits of using electrically conductive inks and coatings as electromagnetic shielding are gaining attention.

DOTITE® offers a wide range of shielding materials that provide an excellent balance of cost and performance by combining selected binders matched to substrates with conductive fillers that impart optimal shielding properties.

Applications

| Product name (code) | Filler | Volume resistivity (Ω·cm) |

Curing/drying conditions |

Storage conditions |

Thinner | Specific gravity | Flash point (°C) |

Attenuation (dB)*1 | Applicable methods | Features |

|---|---|---|---|---|---|---|---|---|---|---|

| FA-323 | Ag | 4×10-5 | 135℃ 10min. | Room temperature | P Thinner | 2.6 | 69 | 50~80 | Screen printing | Used in EMI shielding for FPCs |

| XA-1110 | Ag | 9×10-5 | 150℃ 30min. | Refrigerated | SH Thinner | 1.8-2.2 | 71 | 55~90 | Paintbrush, spatula, spraying* | High reliability, good conductivity, used with smartphone semiconductors |

| XA-5713EE | Ag | 8×10-5 | 150℃ 30min. | Frozen | Solvent-free | 3.9 | 130 | 60~90 | Screen printing (suitable for vacuum printing) | Good vacuum printability, used in wireless semiconductors |

| XA-9015 | Ag | 5×10-5 | 25℃ 3H. 100℃ 10min. |

Room temperature | 9015 Thinner | 2.2 | 22 | 55~90 | Paintbrush, spatula, spraying* | High reliability, good conductivity, good shielding effect, toluene-free |

| FE-107-1 | Ag-Cu | 5×10-4 | 25℃ 3H. 100℃ 10min. |

Room temperature | #884 Thinner | 1.9 | 4 | 55~90 | Paintbrush, spatula, spraying* | Good conductivity, low cost. Used widely in displays, measuring devices, etc. |

| FN-101 | Ni | 5×10-3 | 25℃ 3H. 100℃ 10min. |

Room temperature | #884 Thinner | 2 | 4 | 40~85 | Paintbrush, spatula, spraying* | Non-metallic color in appearance, used in exposed applications for its resistance to discoloration |

| XA-5905 | Ag | 3×10-4 | 150℃ 60min |

Frozen | Solvent-free | 3.5 | 130 | – | Dispensing, transfer printing | Connecting and bonding semiconductor packages to circuit boards |

- For spraying, we recommend diluting with thinner before use.

*1 Measured with the KEC method (10 MHz to 1 GHz).

All of the above product lines comply with the European RoHS Directive.

The above values are all representative values, and do not represent full product specifications.

Electrostatic Shield

While electronics are becoming increasingly ubiquitous, interference with electric circuitry and electronic parts caused by electrostatic noise and induction can still be a cause of malfunctions.

By applying shield paints, static induction can be controlled, reducing interference from external noise.

| Product name (code) | Resin | Volume resistivity (Ω·cm) |

Drying conditions | Applicable substrates | Thinner | Features | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Metal | Urethane | ABS | NORYL/ XYRON |

PS | PC | Acrylic | FRP | PP | ||||||

| XC-9064 | Polyolefin | 10-1 | 25℃ 3H. 100℃ 10min. |

◯ | △ | ◯ | ◯ | ◯ | ◯ | ◯ | △ | ◯ | XC-32 Thinner | Dries in air, adheres well to a variety of substrates including PP |

| SH-3A | 2-component epoxy | 1 | 25℃ 24H. 100℃ 60min. |

◯ | ◯ | – | ◯ | ◯ | – | ◯ | ◯ | △ | SH Thinner | Dual-component coating, cures at room temperature, adheres to a variety of substrates |

- For spraying, we recommend diluting with thinner before use.

All of the above product lines comply with the European RoHS Directive.

The above values are all representative values, and do not represent full product specifications.

About the Division

For an introduction to the business division, its strategies, and where its products are used, please refer to the business overview page.