Occupational Safety and Health

Occupational Safety and Health Policy

Occupational Safety and Health Policy

- As a company that handles chemical substances and chemical reactions, we will introduce an occupational safety and health management system and make continuous improvements to ensure the system is effective.

- We will aim to create a safe, healthy and comfortable workplace by setting occupational safety and health targets, evaluating our degree of achievement of these targets and disseminating occupational safety and health activities across the company.

- We will comply with laws and regulations on safety and health that apply to our business activities, as well as with requirements that we have agreed to and voluntary standards we have adopted independently.

- We will provide safe and healthy working conditions to protect our personnel from injury and illness.

- We will promote communication (discussion, participation) with all employees and implement occupational safety and health activities with full employee participation.

- We will provide our personnel the education, drill and safety guidance that is needed to raise their awareness of the importance and their responsibility to maintain safety and health.

- We will disseminate our Occupational Safety and Health Policy to all personnel in writing.

- We will disclose our Occupational Safety and Health Policy to the public.

Fujikura Kasei Co., Ltd.

President

Daisuke Kato

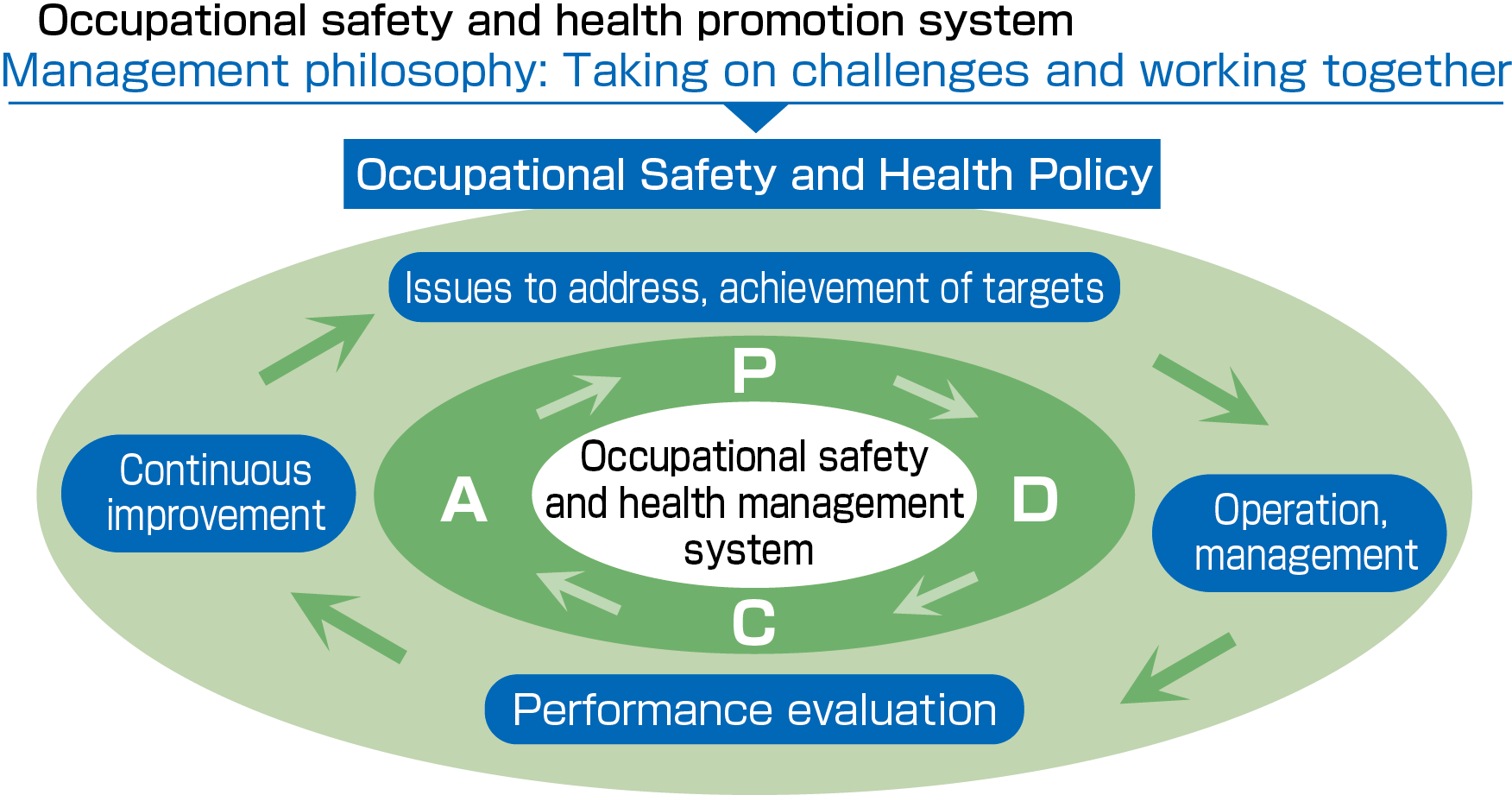

Occupational safety and health management system

Occupational safety and health management system

In December 2019, we switched to an occupational safety and health management system in accordance with ISO45001:2018. We moved from the conventional BS-OHSAS 18001:2007 certification, obtaining the new certification from an external authority in November 2020. We will continue our activities to realize a comfortable working environment with no occupational accidents.

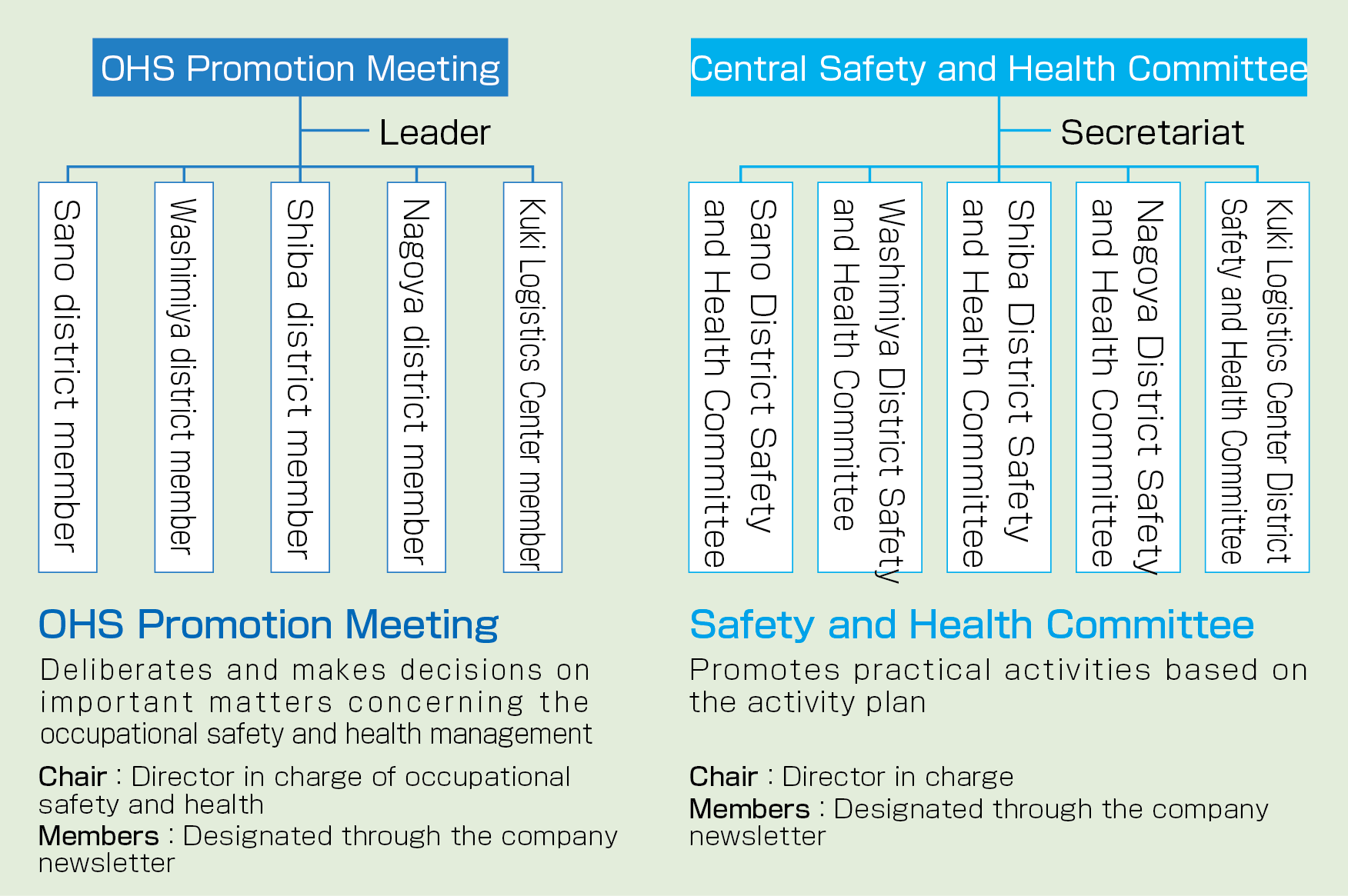

Occupational safety and health promotion framework

The promotion framework brings together the management system and practical aspects of occupational safety and health by combining the previous OHS Promotion Meeting and the Safety and Health Committee. Through this framework, we promote activities that widely incorporate the views and proposals of all employees, and aim to achieve zero industrial accidents and realize a comfortable workplace environment.

- Occupational Safety and Health Information Reporting to the Board of Directors in FY2023: 12 times per year

- Occupational Safety and Health Consultations with the Labor Union in FY2023: 4 times per year

Activities to achieve zero occupational accidents

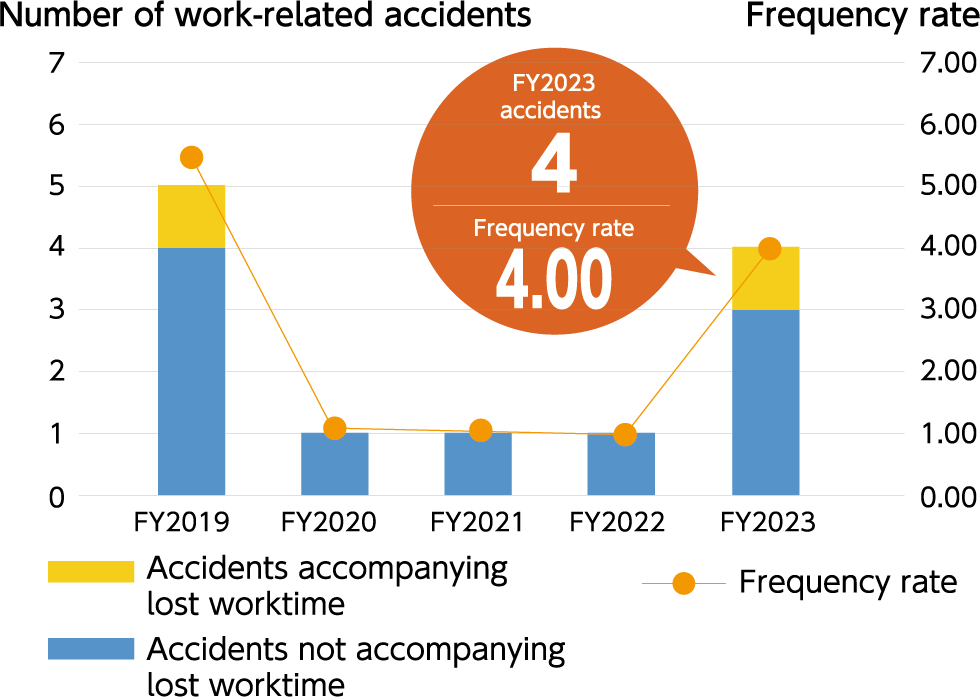

Number of occupational accidents

In fiscal 2023, there was one accident resulting in lost worktime and three accidents not resulting in lost worktime. Thus, we failed to achieve our goal of zero occupational accidents. In terms of the types of accidents, two involved coming into contact with a harmful substance, one involved a cut or abrasion, and one was a fall or collision accident. Taking the occurrence of these accidents seriously, we will strive to prevent future occupational accidents by reviewing the sources of danger that have been identified in past incidents and risk predictions and re-examining the relevance and effectiveness of our countermeasures.

Number of work-related accidents and their frequency rate

Indicators of occupational accidents

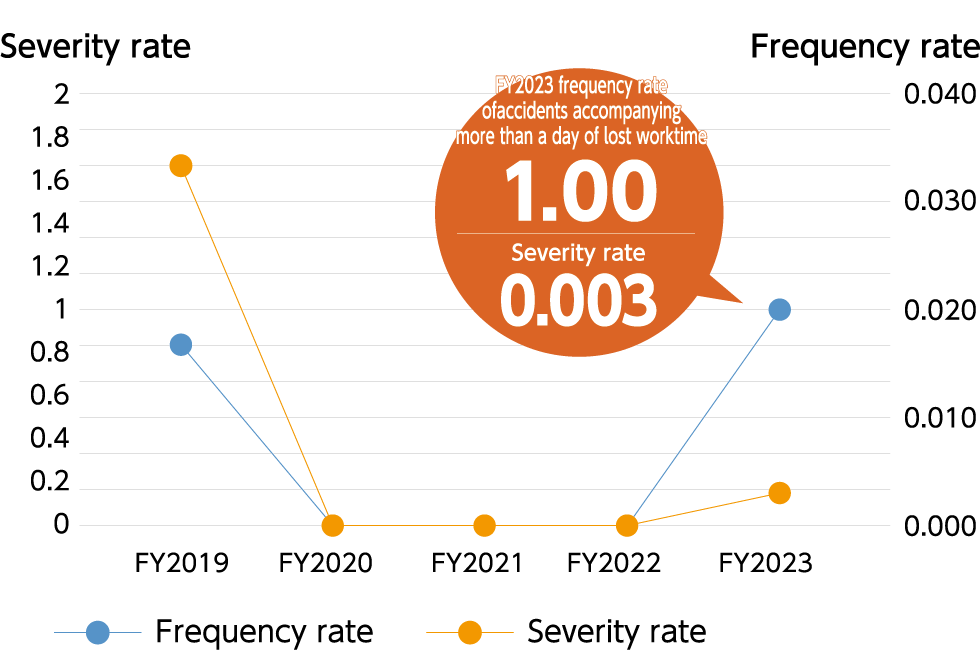

In fiscal 2023, there was one accident resulting in lost worktime. Therefore, the results showed a frequency rate of 1.00 and a severity rate of 0.003. The accident occurred when an employee going down the stairs fell and sprained an ankle and could not work for three days. Such an accident is difficult to prevent, but we intend to avoid it as much as possible by disseminating basic actions such as using the handrail when going down the stairs. We will continue to monitor occupational accidents using the frequency and severity rates of accidents resulting in more than a day of lost worktime as indicators.

Frequency rate and severity rate of accidents accompanying more than a day of lost worktime

Safety best practices

Risk prediction (KY) activities

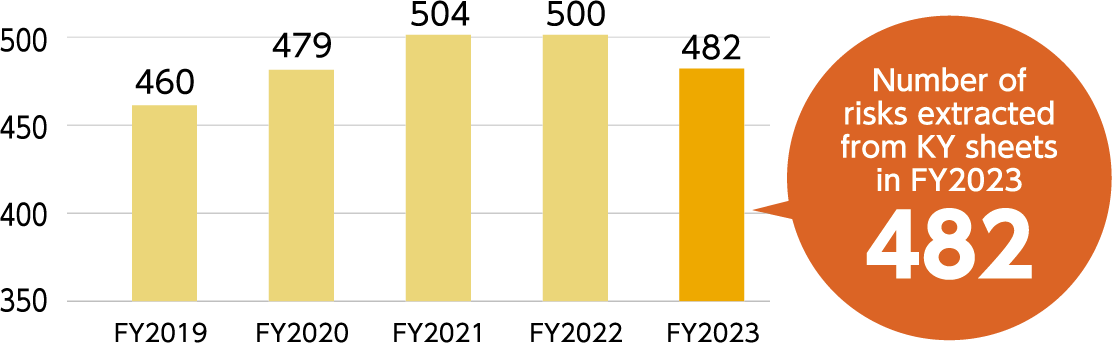

Every year at Fujikura Kasei we engage in activities to predict potential risks across the company. In fiscal 2022, we identified 500 potential risks (99% on last year) within the company. Needless to say, we are working hard to reduce the number of potential safety and health risks at each business base. We aim to achiev e zero occupational accidents by raising awareness among all employees of this idea, continuously minimizing potential risks.

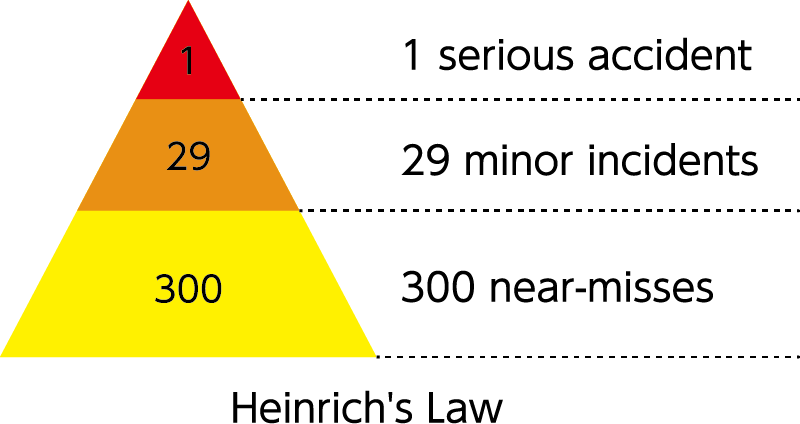

Industrial accident = Unsafe situation × Unsafe act

Number of risks extracted from KY sheets at Fujikura Kasei

Installation of pedestrian paths in the factory <Sano Plant Factory No.1>

In fiscal 2023, a sweeping review was made of pedestrian paths in Factory No. 1 at Sano Plant to prevent contact accidents involving pedestrians and cargo-handling operations in the factory. By color-coding pedestrian walkways and crosswalks in the factory to maintain an appropriate distance between pedestrians and on-site cargo handling vehicles, the plant aims to achieve zero contact accidents on its premises.

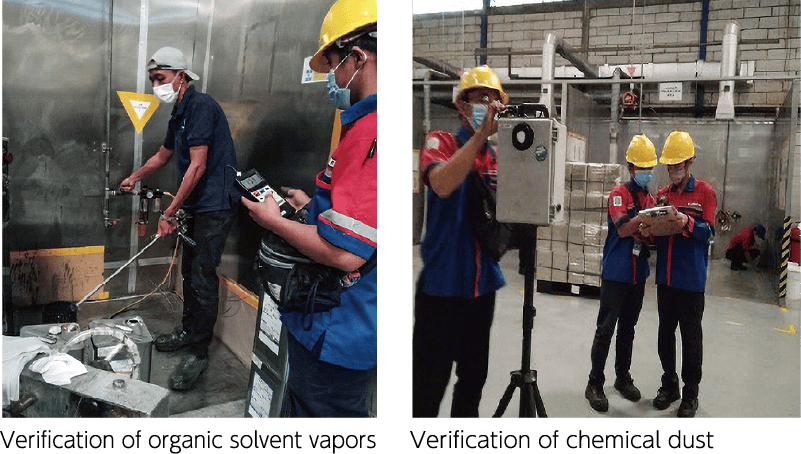

Activities for assessing occupational safety and health in workplace environments <Fujikura Kasei Indonesia>

Fujikura Kasei Indonesia employs an external party to assess the status of occupational safety and health in its workplace environments. Assessment items include "chemical dust," "organic solvent vapors," and "hand vibrations when using a hand mixer," in addition to "room temperatures," "brightness," "noise," and other such items. By conducting assessments from various angles and verifying the status of compliance with the Act on Workplace Environment and Occupational Safety and Health, the company strives to improve working environments and create a safe and comfortable workplace.

Documentation of chemical substance safety training for production personnel <Fujichem Sonneborn>

Fujichem Sonneborn has created a manual for training production personnel in chemical substance safety, also to be used for training new employees. It provides process-specific guidance such as on protecting oneself from chemical substances, wearing work clothes properly, ensuring compliance with work instructions, and reporting dangerous situations. Records of completed training programs are stored in the form of electronic data by training item, and a system is in place that allows easy retrieval of this information.

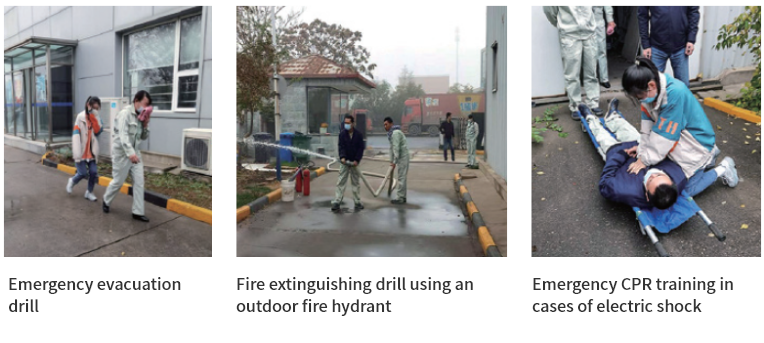

Implementation of emergency drills to strengthen emergency response capabilities <Fujikura Kasei Coating (Tianjin)>

At Fujikura Kasei Coating (Tianjin), efforts are made to strengthen employees’ emergency response capabilities by providing training on emergency evacuation, fire extinguishing using outdoor fire hydrants, and emergency cardiopulmonary resuscitation (CPR) in cases where an operator in the distribution switchgear room receives an electric shock.

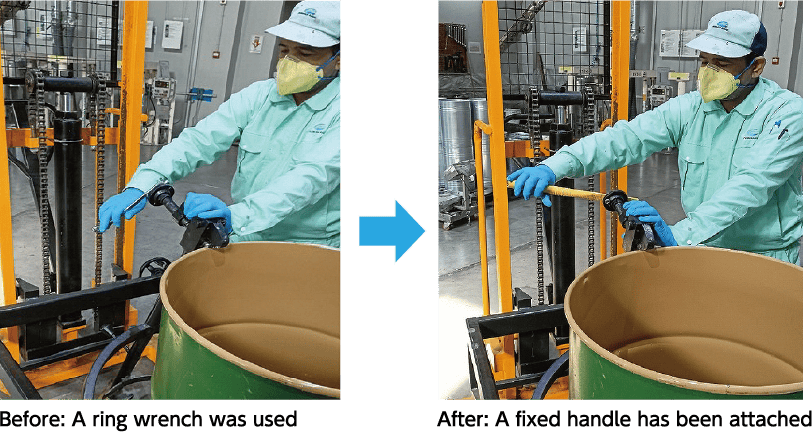

Improvement in fixing the barrel lifter in place <Fujikura Kasei Coating India>

At Fujikura Kasei Coating India, a ring wrench was conventionally used to secure the barrel lifter and drum cans when lifting and lowering the cans. However, it has been replaced with a fixed handle for enhanced safety. The change is expected to reduce the risk of occupational accidents, such as fall incidents that may occur during drum lifting.