Environmental & Social Contribution through Business

At Fujikura Kasei, we pursue environmental and social contribution activities through our business practices, to fulfill our corporate social responsibility.

Initiative Examples

Reducing CO₂ emissions from coatings containing non-edible biomass

Shifting from petroleum-based materials to renewable, non-edible biomass materials accords with the food issue accompanying the growing global population and is a critical step towards achieving carbon neutrality. Thus, the Coatings for Plastics Division proposes coatings that utilize non-edible biomass and deliver the required functions while contributing to a recycling society. Since biomass contains carbon absorbed by plants from the air, it supports decarbonization. We will continue to propose environmentally friendly choices to help realize a sustainable society.

RECRACK5800FM-R series

Maintaining the beautiful appearance of architecture with an ultra-low-stain clear coating

As part of our ongoing efforts to add value to architectural structures, we have launched a water-based, single-component, ultra-hydrophilic (ultra-low-stain) top coat developed in collaboration with the Technology Strategy Promotion Office. With the increasing need to prevent stains on highly durable exterior walls, this topcoat delivers hydrophilic surface properties, reducing static electricity on the exterior surface and minimizing the adherence of dirt. During a rainfall, water seeps behind the dirt, lifting and washing it away. Additionally, the paint displays a temporary color (red) to prevent uncoated area during application, ensuring consistent quality. The color naturally disappears over time. We will continue to develop products that contribute to reducing environmental burden.

Reducing VOC emissions from water-based conductive pastes

The Electronic Materials Division has developed and launched the new D900 series of water-based conductive pastes that cure at room temperature. Conventional room-temperature-curing conductive pastes have been used widely as conductivity reinforcement in screws and rivets, simple conductive bonding for holding SEM samples, circuit repairs, and as a base layer for electroplating.

Since the new product is free of volatile organic compounds (VOC), it minimizes air pollution and potential health risks. We will continue to provide products that help reduce environmental impact and contribute to realizing a sustainable society.

Contributing by refraining from using environmentally harmful substances

Synthetic polyurethane generally contains environmentally harmful substances such as NMP (N-methyl-2-pyrrolidone) and organic tin compounds. In response to strengthening regulations, our company has adopted a policy to refrain from using certain raw materials. This has allowed us to play a part in reducing the impact on the global environment and realizing a sustainable future. By offering environmentally friendly polyurethane binders, we are actively working with society to build a better world. Additionally, we are committed to introducing, reusing, and recycling eco-friendly alternative raw materials. These initiatives are not simply business strategies to us; they are rooted in our ethical values and sense of mission. We will continue our efforts to pass on a better environment to future generations.

Inkjet binder

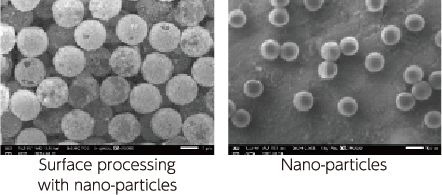

Contributing to enhanced diagnostic performance with high-function particles

By the enhanced performance of latex turbidimetry, diagnosis items that required high-precision measurements using dedicated equipment can be verified by simpler, more universal tests. This will not only improve convenience for hospitals and testing centers but will also promote the early detection of diseases in medical examinations.

The Medical Materials Department is enhancing the functionality of latex turbidimetric reagent raw particles and providing them to domestic and international reagent manufacturers to help improve the performance of reagents.

Additionally, we are replacing some of the bottles used for our products with biomass-based bottles to reduce CO₂ emissions associated with our products.

Effectively utilizing resources and promoting a sustainable business model

Acrylic panels were widely used to prevent droplet infection during the COVID-19 pandemic, but as they are no longer used, we collected them from our customers and sold them to recycling companies as reusable resources. This initiative has not only contributed to effective resource utilization and environmental protection, but it has also made it possible to promote a sustainable business model. We will continue our efforts to reduce environmental impacts and ensure the effective utilization of resources toward realizing a sustainable society.

Effective utilization of acrylic boards as resources